How to make a spinning grip that allows you to adjust the grip length

Recently, it seems that there are more and more anglers who are not sticking to one type of fishing, but are going out to various fields to catch various fish species. The rod and the grip are one. Hitotoki Works believes that the appearance of a fishing rod, which has been common until now, is no longer a suitable fishing tool for the diversifying anglers. Wouldn't it be exciting if the length of the rod and grip could be adjusted with one touch to suit the fishing or the area?

We will introduce you to the dream grip making method devised by Hitotoki Works, perfect for the fun-loving and active angler.

Grip Joint System

First, let me explain the "Grip Joint System" that allows you to attach and detach the rod. This system allows you to fix the rod equipped with an aluminum ferrule called a champion ferrule.  It can be attached as a front grip to a wooden reel seat or a typical Fuji Industrial plastic reel seat, making it possible to attach and detach the rod with a single touch.

It can be attached as a front grip to a wooden reel seat or a typical Fuji Industrial plastic reel seat, making it possible to attach and detach the rod with a single touch.

For more information, please see the Grip Joint System page.

See the Grip Joint System explanation page

The grip to be produced this time

The handle we will be making this time is a product sold by Hitotoki Works under the product name "Chameleon Handle". As the name suggests, this handle can change its style flexibly according to the situation, just like a chameleon. Not only can you change the rod, but you can also change the length of the end grip to match the rod!

Materials used this time

●Grip Joint System: A silver type cap is also available, but we used the black one for a more subdued, bold and masculine look.

●Spinning reel seat (TVS-16) A reel seat with a brown burst paint finish finished by the craftsmen at Hitotoki Works is used.

●Aluminum parts for hood nuts ( KNR-17 , KTR-17 ) Black for a unified look that matches the color of the grip joint system.

● Winding Check WC (S16-DR)

●Rear grip (CTVSG16-15) and end grip (C27SG-13) This time we'll use cork for everything to create an elegant grip!

●In order to create two different lengths of detachable parallel joint carbon pipe end grips, we have prepared two types of male pipes, as shown in the foreground of the photo.

- ● End parts ( butt end caps )

This time I'll try finishing it with rubber cork.

Required Tools

● Cutter (design knife) Used to remove burrs after cutting plastic parts.

● Vernier calipers Digital types are easier to use and allow for quick measurements.

●By attaching a diamond cutter to the router, cutting carbon pipes becomes incredibly easy!!

● Two-part epoxy bond (5-minute type) A strong bond that starts working after 5 minutes. If you are not familiar with it, use the "30-minute type" that starts working after 30 minutes, and work slowly to reduce mistakes.

● Alcohol Used to wipe off excess adhesive. At Hitotoki Works, we use "fuel alcohol" sold at pharmacies, diluted in half with water to avoid damaging the paint.

●Handy saw Used to cut plastic pipes.

●File: Used to scratch the inside of the carbon pipe to increase the adhesive strength.

●Spacer tape A tape that acts as a gap filler when gluing parts that have gaps.

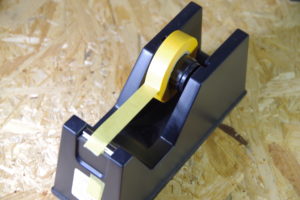

● Masking tape Used for marking when cutting parts. At Hitotoki Works, we set it on a tape stand to make cutting easier. We recommend this method!

●Toothpick Used for small areas when installing winding checks or when applying epoxy bond to the inside of parts.

●Sandpaper: Sandpaper in the #400 range is easy to use.

Step 1: Processing the hood

We will assemble the parts for the hood nut that secures the reel. First, use a vernier caliper to measure the adhesive area of the aluminum part that will be attached to the hood nut.

The adhesive surface is approximately 5 mm, so cut the food pipe so that it is 5 mm long.

■Tips and advice: Instead of marking with masking tape exactly at 5 mm, leave an extra 1 mm for the thickness of the blade, mark with masking tape so that 6 mm remains, and then cut it out with the handy saw.

The cutting of the hood nut is complete, but at this point the cut surface is dirty and there are burrs.

If you have a cutter and paper, use that to clean up the cut surface. If you neglect this step, the burrs will interfere and damage the reel seat, so be careful!!  There will be a small gap between the hood pipe and the aluminum ring, so fill the gap with spacer tape.

There will be a small gap between the hood pipe and the aluminum ring, so fill the gap with spacer tape.

The two-component epoxy bond is thoroughly mixed with the base agent and hardener in a 1:1 ratio and applied to the components.

Wipe off any excess glue with a tissue soaked in alcohol.

Step 2 Cut the reel seat screw

The screws on the reel seat body also look a bit tacky if they are too exposed. Let's get rid of the unnecessary parts to make it look cool!  Leave about 32 mm and cut it with a handsaw in the same way as the hood nut.

Leave about 32 mm and cut it with a handsaw in the same way as the hood nut.  As with the hood nut, clean the cut surface.

As with the hood nut, clean the cut surface.  Finished!!

Finished!!  When the reel is attached, the screw on the main body retracts slightly, giving it a stylish look!!

When the reel is attached, the screw on the main body retracts slightly, giving it a stylish look!!

Step 3 Gluing the reel seat

The reel seat and aluminum ring are glued to a female carbon pipe with an outer diameter of 15 mm.

Just like when gluing the aluminum ring of the hood nut, mix the base agent and hardener of the two-part epoxy bond in a 1:1 ratio and apply it to the parts.

■Tips and advice : When gluing, do not just apply glue to the carbon pipe. Applying glue to the inside of the reel seat with a thin rod such as a toothpick will prevent adhesive failure.

Remove the hood nut, as it will get in the way, and glue the tip of the reel seat with about 8 mm of glue sticking out. Wipe off any excess glue with a tissue soaked in alcohol.

Apply a small amount of epoxy glue with the tip of a toothpick and attach the winding check.

Step 4: Installing the Grip Joint System

Before attaching the receiving part of the Grip Joint System and the Winding Check, scratch the inside of the carbon pipe to increase the adhesive strength. Make sure to scratch it firmly with a file or similar.

After the mounting work is completed, clean it with alcohol and then apply adhesive. Apply adhesive not only to the grip joint system side but also to the inside of the carbon pipe.

Install the hood nut that was removed earlier, and insert the receiving part of the grip joint system that has been coated with adhesive and the winding check.

Wipe off any excess adhesive thoroughly.

Wait a while for the adhesive to harden, and it's done! It's gradually starting to take on the shape of a grip.

Step 5: Installing the rear grip and winding check

Now that we've come this far, all that's left is some simple work that isn't too difficult. Let's get started! First, measure the length of the rear grip and winding check, and mark it with masking tape.

Cut the carbon pipe with a router! If you have a router, you can cut it in about 10 seconds, so your work will go faster.

Use sandpaper to smooth out the cut surface. At this time, be sure to use sandpaper to round not only the cut surface but also the corners (both the outside and inside).

After roughening the surface of the carbon pipe, apply epoxy bond to the carbon pipe and the inside of the grip, and wipe off any excess glue.

The base grip is complete!

Step 6 Making the end grip

This is the last step!! We will make two types of end grips that can be inserted into the base grip to make them removable.

First, cut the 13mm male carbon pipe to the desired length. This time, I cut it to a 100mm short type that can be used in mountain streams, and a 140mm long type that can be used for various fishing such as bass and main stream trout.

Glue the winding check and end grip with epoxy glue.

All that's left is to attach the butt end. There will be a gap between the shaft of the butt end and the inside diameter of the carbon pipe, so fill the gap with spacer tape.

Thoroughly apply glue to the inside of the carbon pipe as well, and once it hardens, it's complete!!

Completed

●Short type end grip specification The total length of the entire grip is now 267 mm.

●Middle type end grip specification The total length of the entire grip is now 312 mm.

This completes a grip that not only allows you to replace the rod, but also allows you to adjust the grip length. Please give it a try. This video shows how to make a ferrule from a ready-made rod. Please refer to it. https://youtu.be/wGucbh9yoik